X-Ray Fluorescence Laboratory (XRF Lab)

Overview

The X-Ray Fluorescence Laboratory (XRF Lab) is a partner of the C4G Consortium (Collaboratory for Geosciences – the national research infrastructure for Geosciences), also member of the European Plate Observing System (EPOS). Currently, the XRF Lab scientific coordination is assigned to António Mateus, assisted by the chief operator and Lab manager Pedro Celestino Rodrigues.

The primary purpose of this lab facility is to gather high sensitivity, multi-element analyses of whole-rock and mineral concentrates. The X-ray fluorescence spectrometry is widely used in geochemical analysis, and the main reasons for that choice are the simple sample preparation, and the good to excellent detection limits across large part of the Periodic Table. Therefore, the main scientific domain is Geochemistry (and all its applications, from Petrology to Metallogeny, also extending to Geochemical Exploration, Environmental Geochemistry, and Medical Geology).

The XRF Lab was reassembled in 2018, replacing an XRF spectrometer acquired in the 1980s, whose rehabilitation was no longer possible. The acquisition of a new wavelength dispersive spectrometer allowed, in a first phase, the geochemical analytical work restoration at FCUL, despite several setbacks caused by malfunctions in other components (e.g. chiller system) that had to be replaced in the meantime. The new equipment has been routinely used since the end of 2019, recording an increasing demand from researchers and postgraduate students from the Geology Department of FCUL and the IDL’s RG3 and RG2. Additional efforts have been made to increase the operability of the equipment and its productivity (see below). According to available information, the XRF Lab will soon have two new pieces of equipment (already purchased) that will considerably increase the Lab’s output and scientific relevance. Expectedly, these technical improvements will also increase the installed response capacity, as well as the external demand, both from other national research units and companies. These new lab capabilities will be suitably released in our collaborative networks, such as the C4G.

Since its refoundation, the XRF Lab assisted the work of 23 MSc students, 5 PhD students, 2 IDL researchers, 1 foreigner researcher (in sabbatical at FCUL), providing a growing number of geochemical datasets included in several lines of (fundamental and applied) research (≈55-60%) and in post-graduate training/studies at FCUL (≈40%); the weight of graduate training is residual (<5%) and mostly confined to the “Project” curricular unit.

So far, all the financial costs with the EPMA Lab are being supported by research (national and European) projects and service provision requested by companies. Note that the acquisition of the new wavelength dispersive spectrometer was fully supported by funds obtained through services related to technical-scientific protocols established with different companies.

Infrastructure

The EPMA Lab, sited in the FCUL Campus, is part of a series of lab-infrastructures assigned to the compositional characterization of geological materials, which are distributed across the 1st floor of the C6 building (Geology Department).

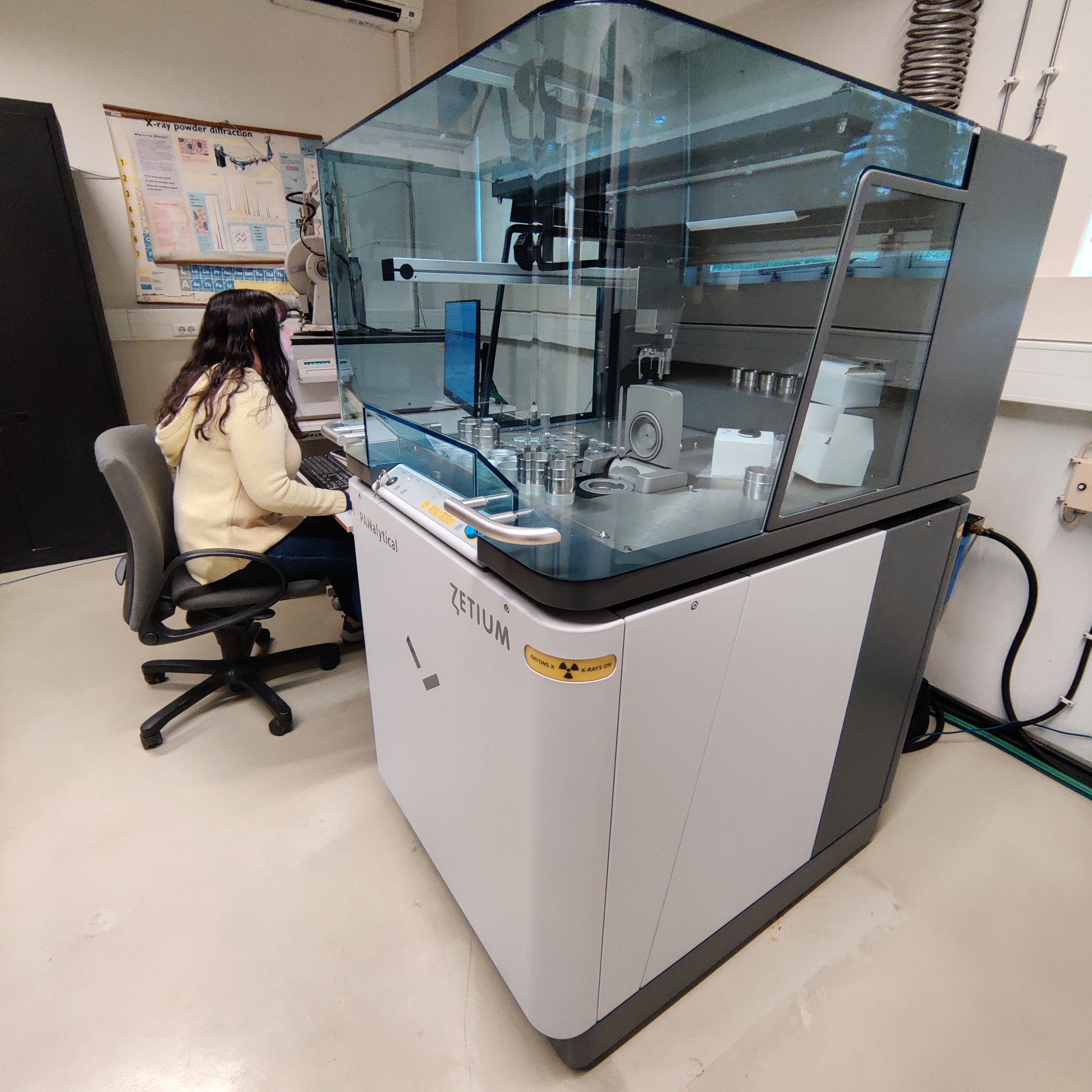

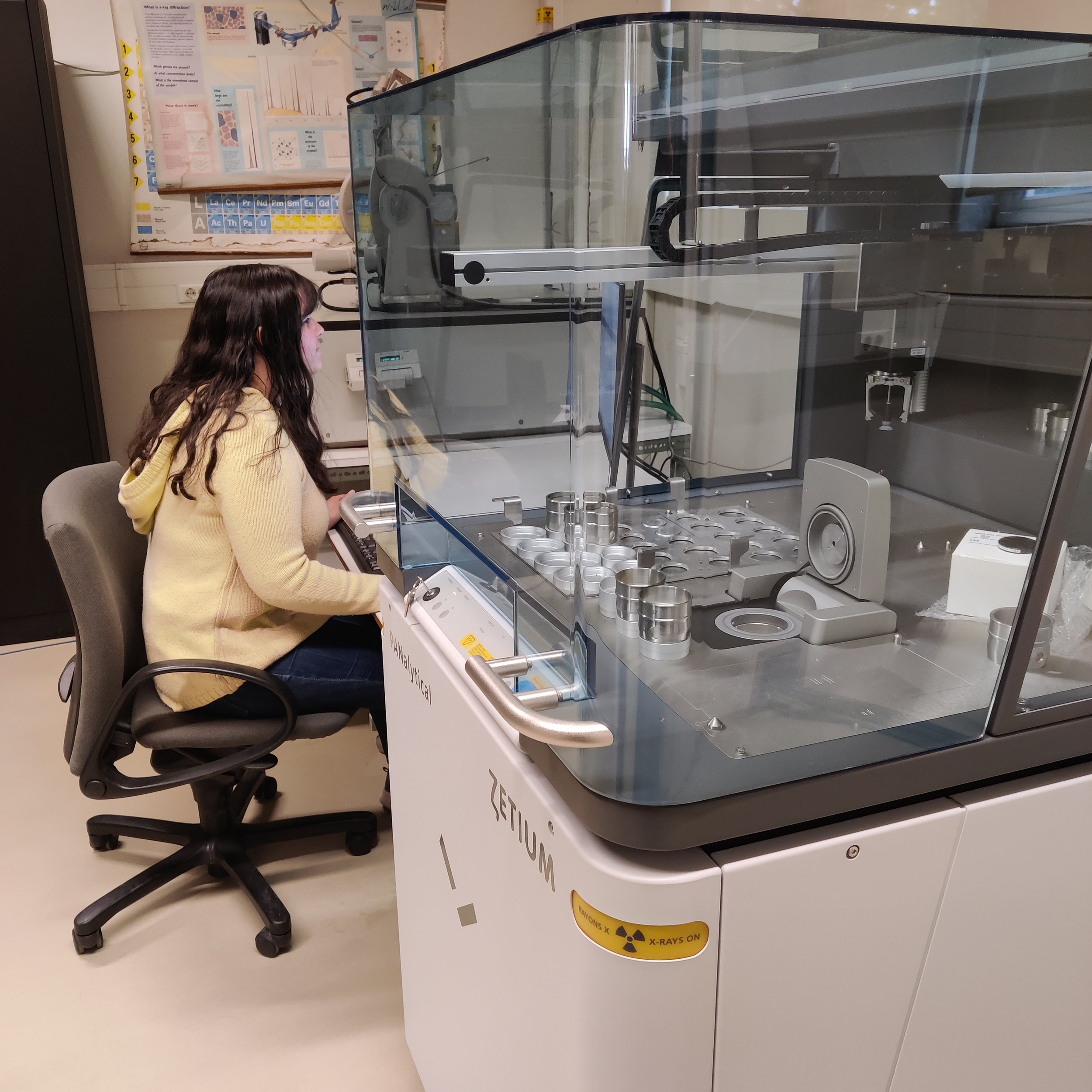

The XRF Lab has one dedicated specialised technician (Pedro Celestino Rodrigues) and uses a wavelength dispersive ZETIUM 4 KW spectrometer (PANalytical) optimised for multi-element, high sensitivity analyses of whole-rock and mineral concentrates. The installed analytical system, connected to an adequate voltage stabiliser to prevent damages caused by sudden failures of the main electrical supply, is designed to provide accuracy, precision, and sub-ppm detection limits for many elements. The Pro-Trace software and existent standards, ensures high quality trace-element analysis of up to 44 elements, targeting a wide range of materials of geological and environmental significance. Currently, we are using pressed pellets for the XRF measurements, produced with a piston-pressure apparatus (between 15 and 35 T) after grinding the sample to a fine particle size (ideally < 50mm) and mixing it with a resin. Very soon we will change this procedure by using the EAGON2 (PANnalytical) instrument for preparing fused bead samples from pulverized geological materials. This fully automatic instrument provides high performance and productivity in the laboratory, as the two melting positions can work independently (in synchronous or asynchronous mode), guaranteeing reproducibility and optimized melting conditions. Using fused beads instead of pressed pellets, as until now, higher levels of analytical accuracy and precision are also ensured. This recent IDL’s investment represents a significant step forward in many ongoing and future research lines in Geochemistry and related scientific fields to be developed at FCUL along with other IDL partners.

To complement the XRF analytical facility, a M4 TORNADO 260 (equipped with two 60 mm2 detectors), produced by BRUKER, was also recently purchased by IDL. The M4 TORNADO is a versatile instrument for fast and accurate high-resolution analysis with X-ray micro-fluorescence (highly sensitive and non-destructive elemental analysis), allowing the use of samples of quite variable dimensions with little or no prior preparation. This equipment, reinforcing the analytical capacity currently available at the XRF Lab, is versatile enough to be used in a myriad of mineralogical and geochemical studies, generating high-resolution compositional maps that optimize the subsequent use of more expensive analytical techniques (e.g., electron microprobe), also enabling the characterisation of samples which compositional nature or textural features makes the corresponding chemical analysis difficult. Besides serving many Geoscience research lines, the M4 TORNADO also increases the installed capacity to offer analytical services abroad.

Main highlights

As mentioned above, the XRF Lab was re-founded in 2018, being operating in routine since 2019, despite of several breaks due to the COVID-19 pandemics and some malfunctions of peripheral components (inherited from the old spectrometer facility) meanwhile replaced. Consequently, the achievements completed over the last 5 years are not impressive, but it is possible to list analytical results provided by the XRF Lab for some articles published in different specialized journals (4) and several master's (23) and doctoral theses (5, already defended or in advanced progress stages). The focus of the analytical activity carried out was on whole-rock geochemistry using samples collected for research projects (some of them still ongoing) dealing with a wide range of issues, although mostly oriented to petrology, geodynamics, and mineral exploration guides. During these studies, care was always taken to double-check the calibration of the ZETIUM XRF spectrometer, analysing rock powders from selected sets of samples in other laboratories, including accredited commercial infrastructures. In this way, it has been possible to check and reinforce the analytical quality of results produced by the XRF Lab, also expanding the number of "in-house-standards" that can be used with confidence in the future (in addition to conventional international standards), covering a very variable range of rocks and ores. Until now, no analytical services were provided for the public or private sector.

Future prospects

Despite the intermittence that has characterised the recent demand for the analytical services provided by the XRF Lab, we believe that IDL's recent investment in the expansion of installed equipment (EAGON2 and M4 TORNADO 260) will make this facility an essential analytical unit to support different lines of (fundamental and applied) research and custom services, being also vital to graduate and post-graduate training in Geochemistry at FCUL. In fact, the production of fused beads with EAGON2 will provide higher levels of performance and productivity. In what concerns performance it is important to emphasise that accurate trace element analysis is becoming increasingly important for many reasons, consolidating the existing avenues or open alternative approaches to many relevant, controversial and still open, scientific issues on many geological processes. Additionally, accurate trace element analysis of geological materials is becoming ever more crucial in a wide range of problems, such as engineering process control with associated cost savings, minimising and checking contamination and environmental pollution during mineral processing, geochemical exploration, and quality control. The optimised use of ZETIUM spectrometer with fused beads produced with EAGON2 will provide the means to achieve the intended detection limits for most elements of geological and environmental relevance.

In addition, the fast and accurate high-quality analysis resolution with X-ray micro-fluorescence (highly sensitive elemental analysis and non-destructive) provided by the recently purchased M4 TORNADO 260 will reinforce the installed analytical capacity of the XRF Lab. This will allow an integrative use of valences provided by the X-ray fluorescence technique, thus complementing the few existing instruments, and improving their inputs to different stages of scientific research, also expanding the analytical portfolio able to attract the interest of some companies for complementary services.

Contact Person

Address

FCUL, Campus, C6 1st floor