X-Ray Diffraction Laboratory (XRD Lab)

Overview

The X-Ray Diffraction Laboratory (XRD Lab) is a partner of the C4G Consortium (Collaboratory for Geosciences – the national research infrastructure for Geosciences), also member of the European Plate Observing System (EPOS). Currently, the XRD Lab scientific coordination is assigned to António Mateus, assisted by the chief operator and Lab manager Pedro Celestino Rodrigues.

The X-ray diffraction is a powerful non-destructive technique for characterising crystalline materials. Thus, the main goal of the XRD Lab is to identify and characterise mineral phases using diffractograms with high signal to noise ratios, even from very low mass samples. In our Lab, this technique could be complemented, whenever necessary, with spectroscopic investigation in transmission mode using the Fourier-transform infrared spectroscopy (FTIR) method, which is based on the infrared spectrum of absorption or emission of a mineral. Thus, the main scientific domain is Mineral Science, embracing all the interfaces between Mineralogy and Crystallography, and wide range applications in (Igneous and Metamorphic) Petrology, Sedimentology and Metallogeny, besides those oriented towards Materials Science and Engineering.

The XRD Lab is a conventional research facility that, in recent decades, has experienced less demand due to the rapid advent of numerous alternative analytical techniques that fully satisfy the needs of many studies. Therefore, requests for X-ray diffractometry studies are much lower than those recorded in past decades, as the interest in structural characterization of mineral phases has decreased among many researchers who carry out their activities at FCUL. It is important, however, to emphasize that this technique remains essential (often irreplaceable) in all lines of fundamental research that include the structural analysis of crystalline phases. It also represents an exceptional technique for characterising mineral concentrates for industrial purposes (e.g. clay mineralogy and its applications), as well as their purity levels.

The activity levels at the XRD Lab are not very high, although there is a reasonable number (≈10) of internal users (researchers and postgraduate students of the Geology Department of FCUL and the IDL’s RG3 and RG2) who continue to use the installed equipment despite some technical problems (see below). Once the diagnosed technical difficulties have been overcome, it is expected that the intensity of demand will increase and, with it, the resurgence of interest in XRD and FTIR. Accordingly, the XRD Lab assists several lines of (fundamental and applied) research (≈80%) and custom services (<5%), being vital to post-graduate training at FCUL (≈10-15%); the weight of graduate training is residual (<5%) and mostly confined to the “Project” curricular unit.

The financial costs with the XRD Lab have been low, reflecting the reduced rate of use of the installed equipment, but most of all due to the successive postponement of the replacement of at least one of the existing diffractometers (see below).

All the funds required to support the XRD Lab result from research (national and European) projects, occasionally complemented with service provisions requested by companies.

Infrastructure

The XRD Lab, sited in the FCUL Campus, is part of a series of lab-infrastructures assigned to the compositional characterization of geological materials, which are distributed across the 1st floor of the C6 building (Geology Department).

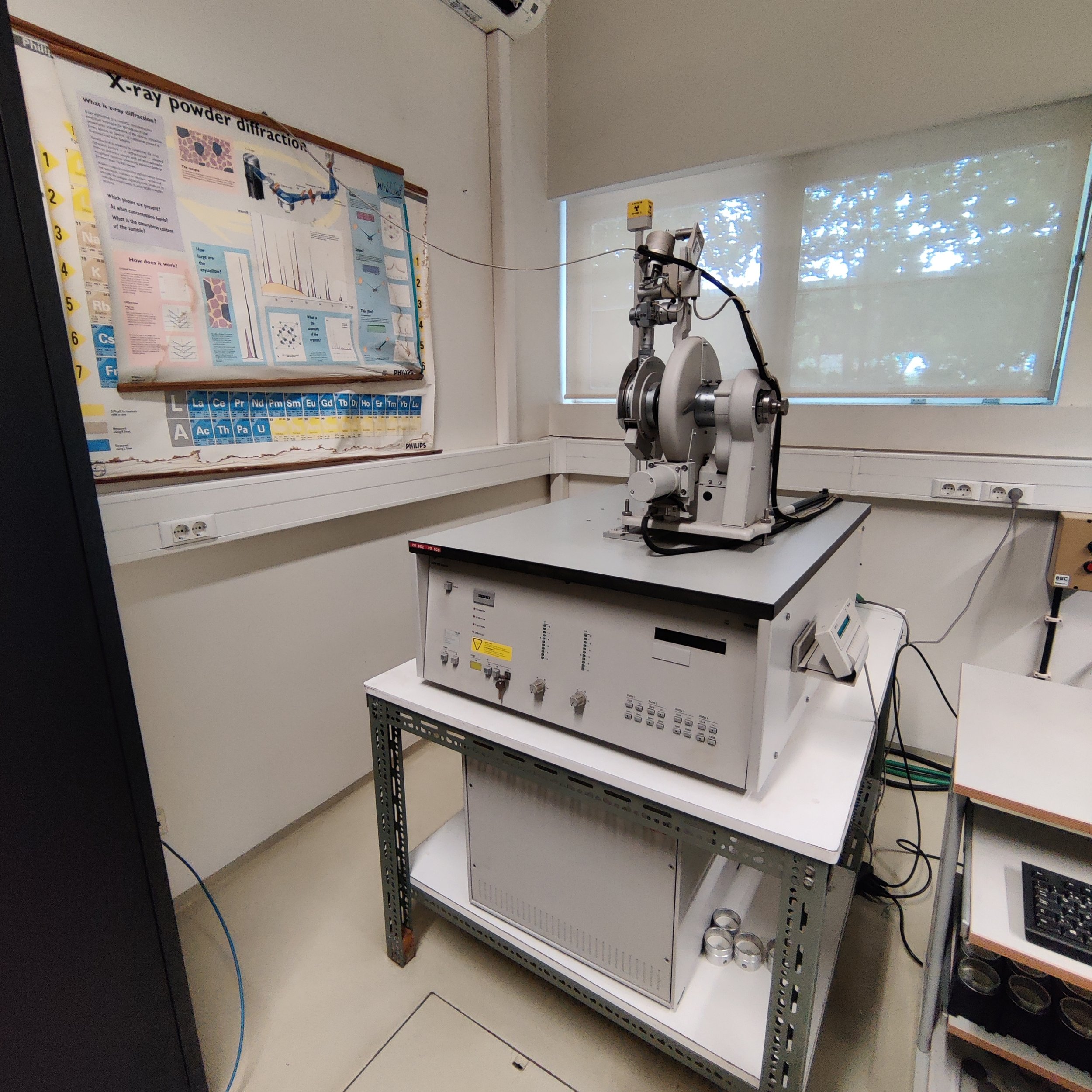

The XRD Lab has one dedicated specialised technician (Pedro Celestino Rodrigues) and uses: (i) an old (>40 years) Philips (PW 1830 + PW1050/37 + PW3710) diffractometer; (ii) a Rigaku Benchtop Miniflex II diffractometer; and (iii) a PerkinElmer Spectrum 100 FTIR. The Philips diffractometer, although operational, shows mechanical wear of some components of the goniometer system, which generates significant measurement inaccuracies for low 2q angles. This creates serious limitations for the equipment use in routine, always requiring the introduction of corrective factors, preventing the development of studies that require high levels of accuracy and precision. The Rigaku diffractometer also reveals some technical problems resulting from intense past use, and whose definitive resolution has not been possible because of obsolete and outdated components that are currently irreplaceable. The equipment requires a reset of the system after each measurement, which raises concern about its functionality in the future. Additionally, the computer and control software of the Rigaku cannot be substituted because of incompatibility of the communication protocols and requirement of specific cables. The FTIR, acquired in 2010, is fully operational.

Main highlights

In the last five years, the analytical results provided by the XRD Lab supported mainly undergraduate training (37) and masters’s theses (4). The number and usefulness (in terms of high-profile publications) of the results obtained with the Phillips diffractometer were seriously compromised because of the systematic error in the goniometer angle readings. The bench top Rigaku diffractometer provided a wealth of outputs in the past that were published in several international scientific journals and continued to support a great deal of post-graduate research and Master theses. The COVID-pandemic period shut the lab and required it to have a full technical check-up, cleaning, and calibration of the components, which was done during the first 6 months of 2022. Since then, the equipment has been used parsimoniously supporting some research work of members of IDL and undergraduate projects. The work included the analyses of clay minerals, complex mineral mixtures of easily disaggregated rocks, and carbonate minerals. Currently the lab does not provide external access to researchers and other public and private entities, although the lab received at least one external enquiry for the commercial use of the analytical results that were requested.

Future prospects

The current configuration of the XRD Lab does not allow to satisfactorily address the current needs, being fundamental the replacement of at least one of the existing diffractometers. Considering the actual demand rate and realistic forecasts for the short to medium terms, it was decided to start the acquisition process of a new bench top diffractometer. The newest Rigaku MiniFlex600 provides an excellent quality for a compact design diffractometer, which presently can supersede the functions of both available diffractometers in the lab, considering the analyses that have been performed so far. The newest equipment is equipped with a 1D SSD detector which increases substantially both the resolution and speed of acquisition of data. Also, the ability to use accessory components of the older Rigaku that maintain compatibility with the new equipment was another aspect for this choice.

Some research areas developed in IDL are still reliant in distinct levels of mineralogical analysis and mineral identification. Therefore, the XRD lab can continue to provide the necessary analyses and support to many Master and PhD theses as it did in the past. This will enable the continuation of research on environmental topics, analysing contaminated samples and complex mixtures of neo-formed minerals, characterization of materials containing clay minerals and others, fine analyses of carbonate minerals to study the transition from Mg-rich calcites to dolomite, among others.

With this equipment, the XRD lab will be able to restore the level of analyses and productivity that once had. It can also respond to the current needs of several IDL researchers that were seeking solutions for shared use of similar equipment with other research labs and departments. Additionally, it will be possible to respond to external requests by public and private entities.

The lab will also implement complementary analyses with the FTIR, especially for the analyses of phyllosilicates and IR-active mineral groups.

Contact Person

Address

FCUL, Campus, C6 1st floor